An eductor, also known as a hootonanny or liquid jet pump, is a simple type of pump that uses the Venturi effect to pump or move a fluid (air, liquid or gas) in an enclosed line. This device has no moving parts, instead relying on only a motive fluid to operate. It provides an efficient system for the addition of water-soluble polymers such as guar gum, polyvinyl alcohol, sugar, starches, sodium alginate, polyacrylamides and more.

An eductor, also known as a hootonanny or liquid jet pump, is a simple type of pump that uses the Venturi effect to pump or move a fluid (air, liquid or gas) in an enclosed line. This device has no moving parts, instead relying on only a motive fluid to operate. It provides an efficient system for the addition of water-soluble polymers such as guar gum, polyvinyl alcohol, sugar, starches, sodium alginate, polyacrylamides and more.

Here are the four main benefits of using SNP eductors when adding dry material into a liquid solution in a mix tank:

- Clump-free solution: Eductors prevent product clumping, which can lead to lower product efficiency, increased product cost, and plugged filters.

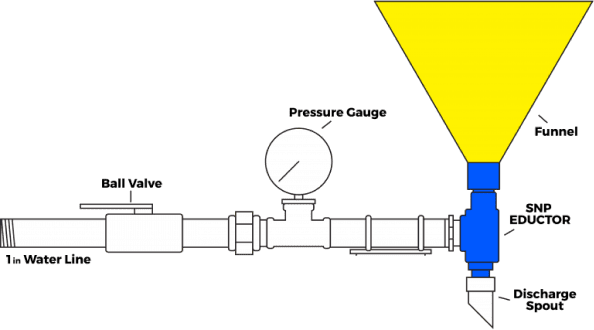

- Simple setup: With no moving parts, eductors feature a simple design. All that’s needed is a properly pressured water inlet, a pipe for discharge, and a support stand or clamps to mount the eductor to the tank.

- Ease of use: The operating procedure for using an eductor is simple and straightforward.

- Easy to clean and maintain: With a simple design, cleaning an eductor only takes a few minutes. Plus, it’s virtually maintenance-free.

SNP’s dry material eductor is easy to install for immediate application and use. See the steps below:

- Connect it to a water source of at least 50 psi to create a strong vacuum.

- Once your water pressure is up to 50 psi, add your material to the intake.

- Allow the eductor to do its job and completely wet and disperse the dry polymer particles.

SNP’s dry material handling eductor can be used manually by adding material via the large funnel or it can be integrated into an automated system. The SNP eductor is designed for long lasting service. SNP stocks a full line of replacement parts should your eductor require service, or a spare dry zone insert. Every SNP dry polymer eductor includes complete installation and usage instructions.

The SNP eductor is designed for long lasting service. SNP stocks a full line of replacement parts should your eductor require service or a spare dry zone insert. Every SNP dry polymer eductor includes complete installation and usage instructions.

When working with dry polymers, it is crucial that they are added and hydrated properly to prevent problems such as lumping or product inefficiency.

If the dry polymer particles are not individually hydrated, clumps of undissolved polymer will form. These clumps could result in plugged filters, ball valves and check valves.

Adding dry polymers too quickly or too slowly can create inconsistent batches in your liquid system, which is why a dry polymer dispenser is essential.

Here are the four main benefits of using SNP eductors when adding dry material into a liquid solution in a mix tank:

- Clump-free solution: Eductors prevent product clumping, which can lead to lower product efficiency, increased product cost, and plugged filters.

- Simple setup: With no moving parts, eductors feature a simple design. All that’s needed is a properly pressured water inlet, a pipe for discharge, and a support stand or clamps to mount the eductor to the tank.

- Ease of use: The operating procedure for using an eductor is simple and straightforward.

- Easy to clean and maintain: With a simple design, cleaning an eductor only takes a few minutes. Plus, it’s virtually maintenance-free.