In the ever-evolving world of coatings and materials science, polyurethane dispersions (PUDs) have emerged as a cornerstone technology, offering a unique combination of toughness, flexibility, and environmental compatibility. At SNP, our advanced polyurethane dispersions are engineered to meet the rigorous demands of modern industries—delivering performance without compromise.

What Makes Polyurethane Dispersions So Special?

Polyurethane dispersions are water-based systems that form tough, flexible films with a wide range of properties. These coatings are known for their:

- Superior resistance to abrasion, chemicals, UV light, and water

- Excellent adhesion to a variety of substrates including metals, plastics, and cement

- Tunable drying times

- pH stability

- Self-crosslinking capabilities for enhanced durability

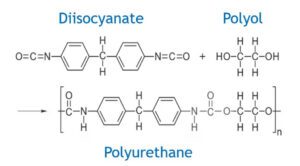

The Chemistry Behind the Performance

At the heart of PUD technology lies a sophisticated chemistry that allows for customization of mechanical and chemical properties, enabling SNP to tailor solutions for specific applications. Below are brief descriptions of the possible components of PUDs:

At the heart of PUD technology lies a sophisticated chemistry that allows for customization of mechanical and chemical properties, enabling SNP to tailor solutions for specific applications. Below are brief descriptions of the possible components of PUDs:

- Diisocyanates:

- IPDI (Isophorone diisocyanate) – aliphatic, UV-stable

- MDI (Methylene diphenyl diisocyanate) – aromatic, high reactivity

- H12MDI – cycloaliphatic, balances flexibility and durability

- Polyols:

- Polyesters – enhance tensile strength and hydrolytic stability

- Polyethers – improve flexibility and low-temperature performance

- Polycarbonates – increase chemical resistance

- Polycaprolactones – improve abrasion and UV resistance

- Chain Extenders:

- EDA (Ethylenediamine), PDA (Propylenediamine) – control molecular weight and crosslinking

Applications Across Industries

SNP’s polyurethane dispersions are trusted across a wide spectrum of markets:

SNP’s polyurethane dispersions are trusted across a wide spectrum of markets:

1. Architectural Coatings

- Interior and Exterior: Low VOC, water-resistant, and available in finishes from matte to gloss.

- Stucco and Cement: High abrasion and chemical resistance with excellent adhesion.

2. Automotive

- Underbody Coatings: High tensile strength, abrasion resistance, and flexibility.

- Direct-to-Metal Topcoats: Superior adhesion and weatherability.

3. Marine and Barrier Membranes

- Designed for harsh environments, offering a balance of tensile strength and elongation with VOCs below 100 g/L.

4. Wood, Metal, and Roof Coatings

- From primers to topcoats, SNP PUDs provide long-term protection and aesthetic versatility.

Product Spotlight

SNP offers over 40 PUD variants, each tailored for specific performance needs. Examples include:

- S-1409-L: High hardness and abrasion resistance for cement and marine

- S-1436-L: High elongation and flexibility for primers and membranes

- S-1452-L: Balanced tensile and elongation for roof and marine coatings

Whether you’re formulating for cement sealants, auto parts, or interior wall paints, there’s an SNP polyurethane dispersion solution designed to meet your needs.

Ready to Elevate Your Coating Solutions?

Let SNP help you find the perfect polyurethane dispersion for your next project. Contact our technical team today to request a sample, schedule a consultation, or learn more about our full product line.