Making eco-friendly, high performance food packaging requires a balancing act from both coating formulation and process to find the sweet spot for competing characteristics.

Send us an email or call to start a conversation about working with us.

Grease and oil resistant substrates can be made by coating paper with per- and polyfluorinated alkyl substances (PFAS) which are the “forever chemicals” that are being phased out because they persist in the environment and are harmful to people.

Water and moisture resistant substrates can be made by laminating polyethylene or paraffin waxes to paper which is then very difficult to recycle and not compostable.

Good news! SNP can help you identify a barrier coating that meets your needs.

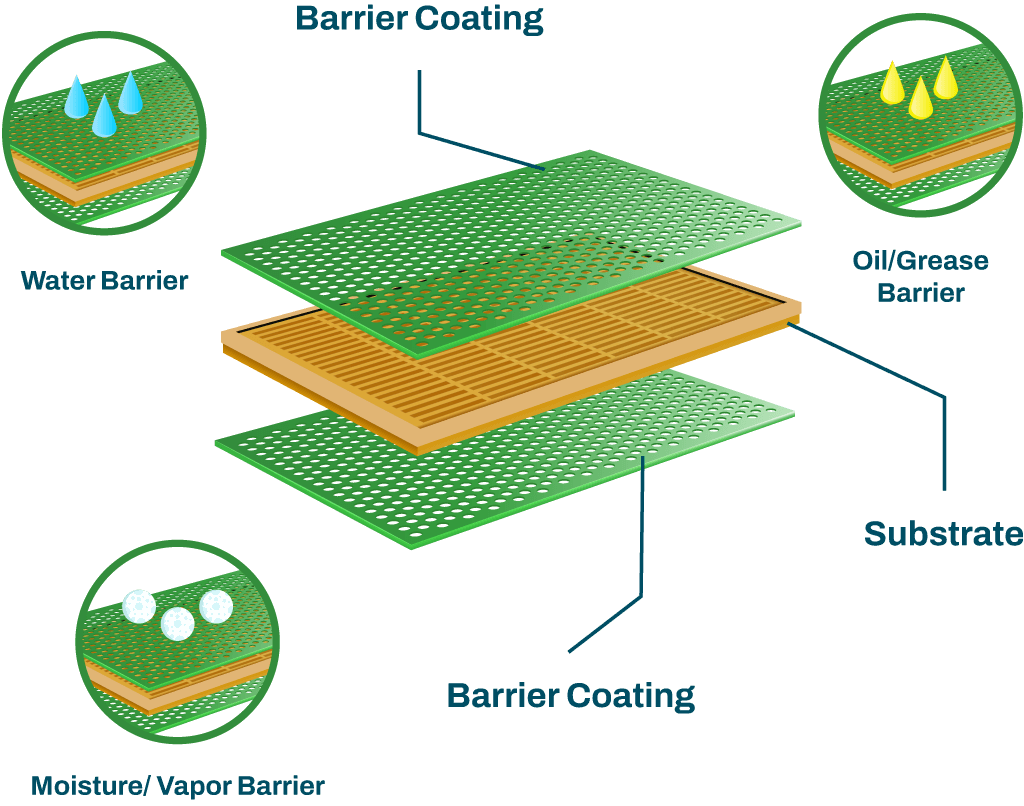

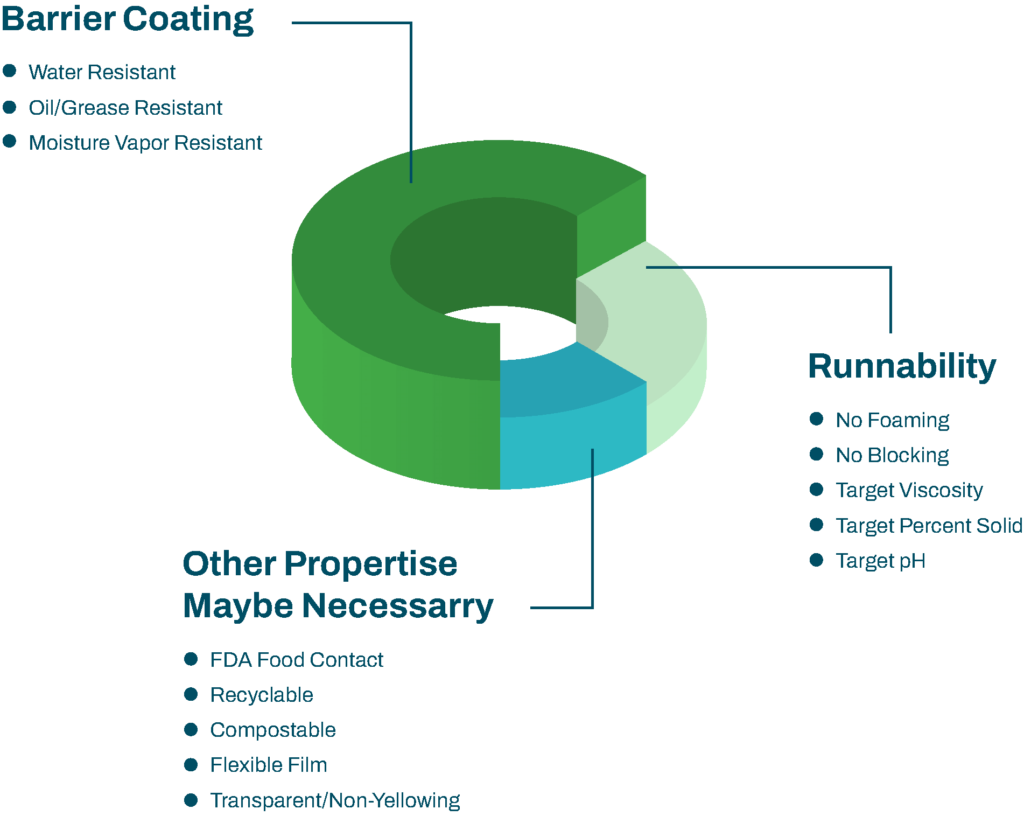

The desired properties for barrier coating may include the following properties:

SNP will work with you to identify the barrier coating that will meet your product specifications and run well in your process.

SNP’s polyvinyl alcohols provide a good barrier for gases, including oxygen, nitrogen, and carbon dioxide and excellent grease resistance.

Sodium alginate is an excellent film former with oil and grease resistance. It is often used with other film formers such as starch and polyvinyl alcohols to improve oil and grease barrier properties.

SNP’s aqueous polyester-based coatings and acrylic/SB emulsions provide good oil, grease, and water barrier. These coatings can be formulated to be:

SNP’s acrylic/SB emulsions are formulated to provide excellent oil and grease resistance (OGR) and a low water vapor transmission rate (WVTR) with proper film formation (pin-hole free).

SNP’s aqueous dispersions of ethylene acrylic acid (EAA) provide outstanding heat seal properties and adhesion to many packaging substrates including metal foil, polymeric film, and paper.

Standard and specialty

Wide range of hydrolysis and polymerization provided as aqueous solution

Aqueous emulsions with good barrier properties

Aqueous emulsions with excellent barrier properties

Ethylene acrylic acid copolymers

Standard and specialty

Wide range of hydrolysis and polymerization provided as aqueous solution

Aqueous emulsions with good barrier properties

Aqueous emulsions with excellent barrier properties

Ethylene acrylic acid copolymers

Ask us about ways we may be able to help you address your product/process issues, develop your new products, and/or meet your custom needs.

Copyright © 2023 SNP, Inc. All Rights Reserved. Privacy Policy

Digital Marketing and Website Design by KNOW YOUR WORTH MEDIA