In February 2024, the FDA made a significant announcement regarding the use of per- and polyfluoroalkyl substances (PFAs) in food packaging in the United States. International regulatory organizations have also implemented bans on PFAs and related compounds. These decisions to cease the use of PFAs stems from growing concerns about their potential health risks and persistent environmental impact. This shift marks a pivotal moment for the food packaging industry, which now faces the challenge of finding effective alternatives that can deliver the same level of performance without the associated health and environmental risks.

PFAs have been widely used in food packaging for their exceptional grease-resistant properties. However, studies have shown that these substances can persist in the environment and accumulate in the human body, leading to adverse health effects. The decision by the FDA in the US and other international regulatory organizations aligns with increasing consumer demand for safer and more sustainable packaging solutions.

High Performance Grease Barriers

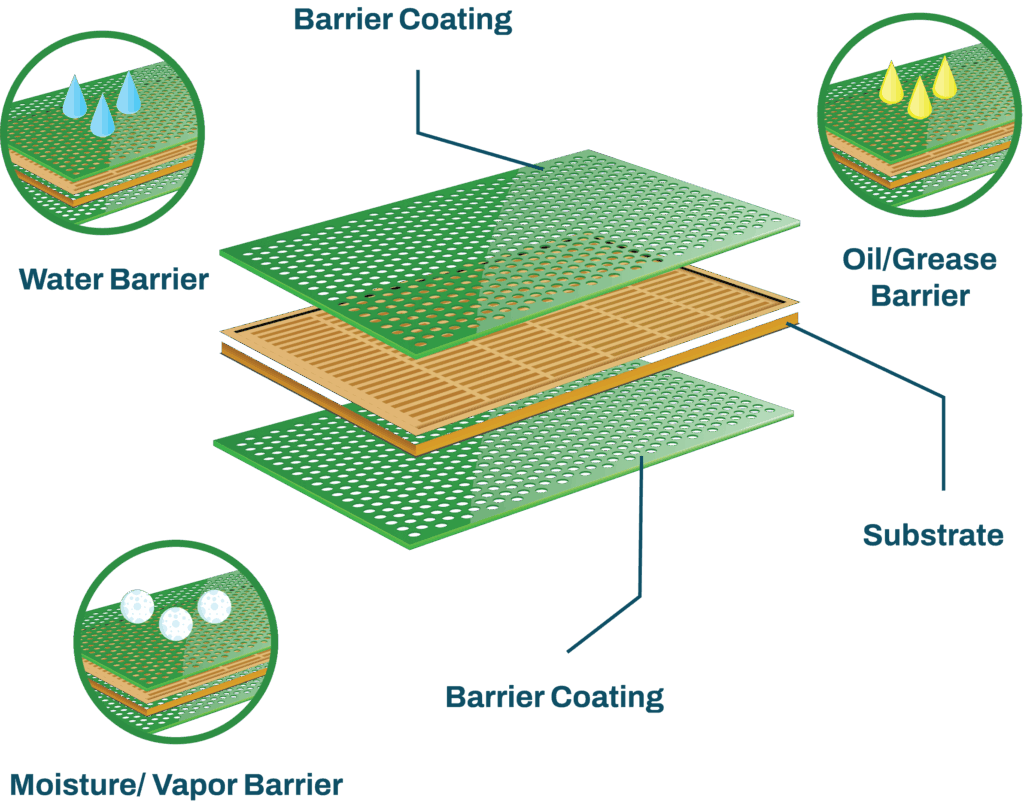

For paper and paperboard manufacturers in the food packaging sector, the transition away from PFAs necessitates the adoption of new materials that can meet stringent performance criteria. SNP, Inc., a US-based manufacturer located in Durham, NC, offers a range of high-performance grease barrier products designed to replace PFAs in coating formulations. These alternatives not only provide the necessary barrier properties but also align with the growing emphasis on sustainability and recyclability.

SNP’s offerings include sodium alginate, polyvinyl alcohols, polyester-based emulsions, and acrylic/SB emulsions. Each of these product lines has been engineered to deliver superior grease and oil resistance, making them ideal candidates for food packaging applications. Additionally, many of these products can be formulated to be repulpable and recyclable, enhancing their environmental credentials.

To learn more check out our Food Packaging page.

Grease Barrier Products

One of the key advantages of SNP’s products is their versatility. The sodium alginates, polyvinyl alcohols, polyester-based emulsions, and acrylic/SB emulsions can be tailored to meet specific requirements for grease and oil resistant barrier coatings, ensuring that they provide optimal performance across a variety of applications. This customization capability is crucial for paper and paperboard manufacturers looking to maintain the quality and functionality of their packaging while transitioning away from PFAs.

Moreover, SNP’s grease barrier solutions offer additional benefits such as glueability, self-crosslinking properties, printability, and edge-wicking resistance. These features enhance the overall utility and appeal of the packaging, providing a competitive edge in the market. By working closely with customers, SNP ensures that their products meet the unique needs of each application, delivering reliable and effective performance.

Contact SNP today to learn more about our products and how we can support your transition to sustainable packaging solutions.

Food Packaging GMP

The Commission Regulations (ED) No 1935/2004 requires that materials and articles intended to come into contact with food “shall be manufactured in accordance with Good Manufacturing Practice (GMP). The rules of such a GMP are described in the Regulation (EC) No 2023/20063. SNP values its customers and prioritizes their needs. SNP has adopted an ISO 9001 Quality Management System and GMP Quality Assurance System for the manufacture of all products, not only those used by our customers in the manufacture of food contact materials, including paper and paperboard food contact materials.

SNP’s GMP Manual includes required components pertaining to implementation of a quality management system, management responsibility and organization, training of personnel, risk analysis, risk assessment and risk management, equipment hygiene and housekeeping, personal hygiene, quality control throughout the process, compliance of starting materials, conformity, storage, shipment, transport and delivery, auditing and management of changes, documentation, labelling, declaration of compliance and traceability of finished goods.

Sustainable Food Packaging

The move away from PFAs in food packaging is part of a broader trend towards sustainability in the packaging industry. Consumers are increasingly aware of the environmental impact of packaging materials and are demanding more eco-friendly options. By adopting SNP’s grease barrier solutions, paper and paperboard manufacturers can not only comply with applicable environmental and safety regulations but also meet consumer expectations for sustainable products.

Repulpability and recyclability are critical factors in this context. Products that can be easily repulped and recycled contribute to a circular economy, reducing waste and minimizing environmental impact. SNP’s emphasis on these attributes reflects their commitment to providing innovative and responsible packaging solutions.

Safe Food Packaging

As the industry navigates the transition away from PFAs, the development and adoption of high-performance alternatives will play a crucial role in shaping the future of food packaging. SNP’s range of grease barrier products represents a significant step forward, offering effective and sustainable solutions that meet the needs of both manufacturers and consumers.

The global food packaging industry has entered a new era, characterized by a focus on safety, sustainability, and performance. Paper and paperboard manufacturers that embrace this change and invest in innovative solutions will be well-positioned to thrive in this evolving landscape.

Custom Barrier Coating

For companies seeking to replace PFAs in their food packaging formulations, SNP offers a comprehensive range of products and expert support. By collaborating with SNP, paper and paperboard manufacturers can ensure that their packaging meets the highest standards of performance and sustainability. More information about SNP’s offerings can be found on our Food Packaging Page.

Eco-friendly Food Packaging

The emphasis on sustainable packaging cannot be overstated. As consumers become more environmentally conscious, the demand for eco-friendly packaging solutions continues to rise. SNP’s commitment to sustainability is evident in their development of products that are not only high-performing but also environmentally responsible. Their focus on repulpable and recyclable materials aligns with the principles of a circular economy, where products are designed to be reused and recycled, minimizing waste and environmental impact.

Furthermore, staying compliant with PFAS regulations is crucial for paper and paperboard manufacturers in the food packaging industry. The US and global bans on PFAS in food packaging highlights the need for companies to adopt alternatives that meet regulatory standards. SNP’s products are designed to comply with these regulations, ensuring that businesses can continue to provide safe and effective packaging solutions without compromising on performance.

Contact SNP today to learn more about our products and how we can support your transition to sustainable packaging solutions.

Innovative Food Packaging

Innovation plays a key role in the development of sustainable packaging solutions. SNP’s use of advanced materials such as polyvinyl alcohols, polyester-based emulsions, and acrylic/SB emulsions demonstrates their commitment to providing cutting-edge products that meet the needs of modern packaging. These innovative materials offer a range of benefits, from superior grease resistance to enhanced printability, making them ideal for a variety of applications.

The development of these materials requires a deep understanding of the chemical properties and performance characteristics needed for effective food packaging. SNP’s expertise in this area ensures that their products are not only innovative but also reliable and effective, providing paper and paperboard manufacturers with the tools they need to succeed in a competitive market.

Sustainable Barrier Coating

Ensuring food packaging safety is paramount. SNP’s products are designed to provide excellent barrier properties, protecting food from contamination and ensuring it remains safe for consumption. By replacing PFAS with high-performance alternatives, SNP helps paper and paperboard manufacturers maintain the integrity of their packaging while also adhering to safety standards.

In addition to safety, SNP’s focus on environmental packaging solutions addresses the growing concern about the impact of packaging on the environment. Their products are formulated to be eco-friendly, reducing the environmental footprint of food packaging and contributing to a more sustainable future. By choosing SNP’s products, paper and paperboard manufacturers can demonstrate their commitment to environmental stewardship and meet the expectations of eco-conscious consumers.

Additional Resources and References

For more information on the transition away from PFAs and the development of sustainable packaging solutions, consider exploring the following resources:

- Environmental Protection Agency (EPA) – PFAs Information – Provides comprehensive details about PFAs, their environmental impact, and regulatory updates.

- European Food Safety Authority (EFSA) – PFAs in Food – Offers insights into PFAs regulations and safety assessments related to food packaging.

- Sustainable Packaging Coalition (SPC) – Innovations in Sustainable Packaging – Features information on innovative materials and sustainable practices in the packaging industry.

- National Institute of Environmental Health Sciences (NIEHS) – PFAs Research – Discusses ongoing research and health effects related to PFAs exposure.

The transition away from PFAs in food packaging is a significant step towards a more sustainable and safer future. SNP, Inc. is at the forefront of this movement, offering high-performance grease barrier solutions that meet the needs of businesses and consumers alike. With a focus on sustainability, compliance with PFAS regulations, and the development of innovative packaging materials, SNP provides the tools necessary for businesses to thrive in a changing market.

For more information on how SNP can help replace PFAs in your food packaging formulations, visit our Food Packaging Page.

Conclusion

The US and global regulations to discontinue the use of PFAs in food packaging underscore the importance of finding safe and effective alternatives. SNP’s high-performance grease barrier products provide a viable solution, combining superior performance with sustainability. As the industry moves towards a future free of PFAs, SNP stands ready to support paper and paperboard manufacturers in their transition, offering innovative products and tailored solutions to meet the evolving demands of the market.

For those in need of high-performing grease barriers to replace PFAs in their food packaging, contacting SNP is a crucial step. With their expertise and range of high-performance products, SNP can help ensure that your packaging not only meets regulatory requirements but also aligns with the growing demand for sustainability and safety.

Contact SNP today to learn more about our products and how we can support your transition to sustainable packaging solutions.