In the evolving landscape of advanced materials, ethylene acrylic acid (EAA) copolymers have carved out a unique niche due to their exceptional adhesion, flexibility, and chemical resistance. EAA copolymers aqueous dispersions offer a wide range of benefits across packaging, industrial, and specialty applications.

What is Ethylene Acrylic Acid (EAA)?

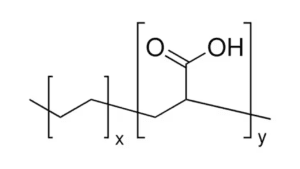

EAA is a copolymer of ethylene (x) and acrylic acid (y), combining the toughness and flexibility of polyethylene with the polar functionality of acrylic acid.

This unique chemistry enables strong adhesion to polar substrates such as metals, glass, and ionomers—making EAA an ideal tie-layer or coating material in multilayer structures.

Key Characteristics of EAA Copolymer Water-based Dispersions

EAA co-polymer water-based dispersions are engineered to deliver:

- Superior adhesion to polar and non-polar substrates

- Excellent heat seal and hot tack performance

- Resistance to environmental stress cracking

- Low odor and taste, critical for food and medical applications

- Puncture and tear resistance

- Water dispersibility, enabling aqueous coatings

What are Benefits of Using EAA Water-based Dispersions?

- Excellent Adhesion: EAA water-based dispersions offer strong adhesion to many substrates ensuring reliable seals with diverse packaging materials, including paper, film, foil, and metallized materials.

- Lower Sealing Temperatures: The lower initiation temperature of EAA can improve packaging efficiency and reduce energy costs as compared to traditional polyethylene (PE) heat seals, starting at 65°C. Lower initiation temperatures may lead to faster packaging line speeds and reduced energy consumption.

- Direct Food Contact Compliance: EAA’s can be formulated to comply with direct food contact regulations, making them suitable for a broad range of food packaging applications.

- Sustainable Packaging: Environmental concerns have led to a growing demand for sustainable eco-friendly and recyclable packaging solutions. EAA copolymer dispersions can be formulated to be compatible with the paper recycling processes. Sustainable paper and paperboard food packaging coated with EAA copolymers offers reduced environmental impact compared to alternative barrier coatings, because they can be recycled without significant issues

What Markets Use EAA Aqueous Dispersions?

The EAA copolymer market is strong and expected to experience growth in the next few years, primarily as a result of the demand in the packaging industry.

Packaging Applications

EAA copolymers are widely used in flexible and rigid packaging due to their barrier properties and sealing performance:

- Aseptic Packaging: Ensures sterility and shelf life for beverages and dairy.

- Laminated Tubes: Used in cosmetics, pharmaceuticals, and toothpaste.

- Condiment Pouches & Sachets: Provides seal integrity and resistance to oils and acids.

- Dry Food Packaging: Offers moisture-resistance and durability.

- Paper Coating: Enhances barrier properties and printability.

More Details about General Application of Heat Seal Coating in Food Packaging:

- Heat seal coatings are crucial for creating strong and reliable seals in various food packaging applications, ensuring product freshness and preventing contamination.

- Flexible packaging, like pouches and bags, uses heat seal coatings to seal the packaging material, forming a secure enclosure for the food product.

- Rigid packaging, like trays and containers, uses heat seal coatings for lid sealing, providing a tamper-evident and protective barrier.

Non-Packaging Applications

Beyond packaging, EAA copolymers serve in diverse industrial and consumer markets:

- Protective Films: For electronics, automotive, and construction.

- Textiles & Nonwovens: Used in hygiene products and industrial fabrics.

- Flooring & Furniture: Adds durability and chemical resistance.

- Wire & Cable Coatings: Provides insulation and environmental protection.

- Protective Metal Coatings: Prevents corrosion and enhances adhesion.

- Digital Printing: Used in HP Indigo printing as a primer to enhance adhesion of the liquid toner to the substrate.

Examples of Products that Use EAA copolymer’s

- Snack Food Packaging: Replacing traditional PE heat seals with EAA dispersions in flexible packaging for chips, pretzels, and other snacks to improve sealing performance and potentially reduce energy consumption.

- Dairy Product Packaging: Utilizing EAA dispersions for lid sealing in yogurt cups or other dairy containers, ensuring a strong, tamper-evident seal.

- Ready Meal Packaging: Applying EAA dispersions to heat-sealable trays or pouches used for ready-to-eat meals, offering reliable sealing and food safety.

- Manufacture of Heat Seal Paper and Paperboard Food Packaging: EAA dispersions can be applied at the size press or off-machine coater to produce food contact grade paper and paperboard materials.

Conclusion

Water-based dispersions of EAA copolymers exemplify the versatility and performance needed in today’s demanding applications. Whether it’s ensuring the integrity of a dry food pouch or enhancing the durability of a carpet backing, EAA copolymers are a cornerstone of modern material science.