SNP custom formulates specialty ethylene acrylic acid (EAA) copolymers aqueous dispersions to meet a wide range of needs across packaging, industrial, and specialty applications. The SNP technical team works with each customer to design and formulate EAA dispersions that meet their specific needs. Send us an email or call to start a conversation about working with us.

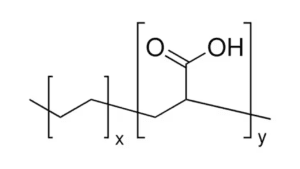

Ethylene acrylic acid (EAA) copolymers provide exceptional adhesion, flexibility, and chemical resistance. EAA is a copolymer of ethylene and acrylic acid, combining the toughness and flexibility of polyethylene with the polar functionality of acrylic acid.

Ethylene unit (x) provides crystallinity chemical, water and moisture resistance and acrylic acid unit (y) provides adhesion, polarity, toughness and strength. Through this combination, EAA copolymers provide resistance to various fluids while providing excellent physical resistance to puncture, tear and abrasion. This unique chemistry enables strong adhesion to polar substrates such as metals, glass, and ionomers—making EAA an ideal tie-layer or coating material in multilayer structures.

EAA copolymer dispersions:

SNP’s S-1900-Series EAA co-polymer water-based dispersions are engineered to deliver:

EAA copolymers are widely used in flexible and rigid packaging due to their barrier properties and sealing performance:

Application of Heat Seal Coating in Food Packaging:

Beyond packaging, EAA copolymers serve in diverse industrial and consumer markets:

Ask us about ways we may be able to help you address your product/process issues, develop your new products, and/or meet your custom needs.

Copyright © 2025 SNP, Inc. All Rights Reserved. Privacy Policy

Digital Marketing and Website Design by KNOW YOUR WORTH MEDIA